In Vitro Research with Stretchable MultiElectrode Arrays (sMEAs)

Bridging the Gap Between In Vitro and In Vivo Research

In vitro research offers several well-known advantages, including tight control of chemical and physical conditions, lower experimental cost, faster turnaround times, and reduced reliance on animal models. These benefits make in vitro systems indispensable for modern biomedical research and drug development.

However, a major limitation of conventional in vitro experiments is their inability to replicate the mechanical and electrical environment of living tissue. Cells cultured on rigid substrates such as glass or plastic often differ significantly from their native in vivo counterparts in morphology, function, and electrophysiological behavior—limiting the ability of in vitro data to accurately predict in vivo outcomes.

The MEASSuRE Platform: Physiologically Relevant In Vitro Electrophysiology

BMSEED’s MEASSuRE system directly addresses this challenge by reproducing the mechanical and electrical microenvironment of cells in vivo within a tightly controlled in vitro setting. The goal of MEASSuRE is to bridge the translational gap between in vitro and in vivo research, enabling more predictive, physiologically relevant experimental data.

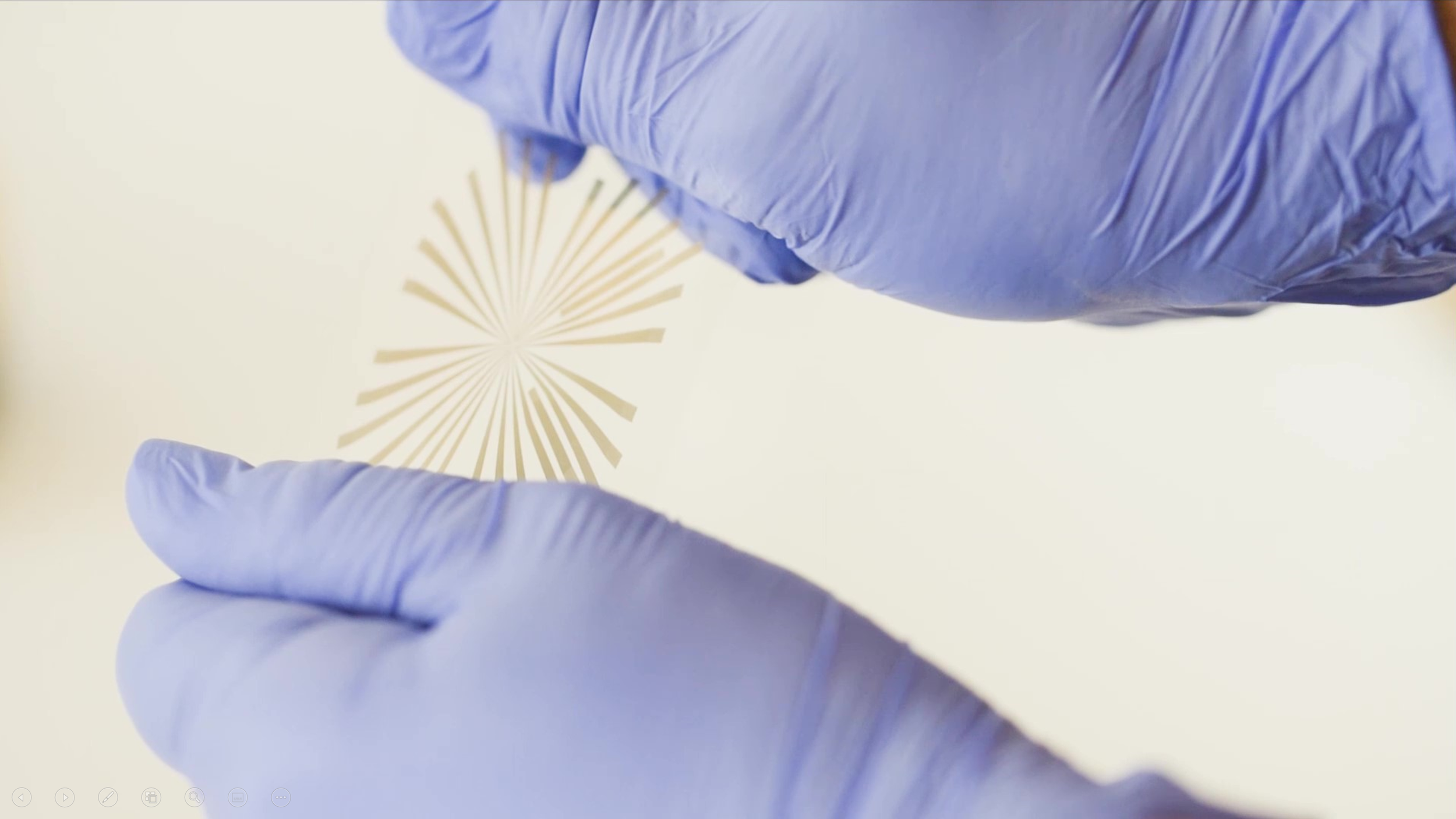

This capability is enabled by BMSEED’s stretchable multielectrode arrays (sMEAs)—silicone-based substrates containing elastically stretchable microelectrodes embedded in an elastomeric matrix that interfaces directly with cell and tissue cultures. The MEASSuRE platform integrates the hardware required to mechanically stretch, optically image, and electrically stimulate and record from cultures grown on stretchable MEAs.

No More Trade-Offs Between Mechanics and Electrophysiology

Historically, researchers had to choose between applying biomechanical cues or performing electrophysiological measurements in in vitro studies. With MEASSuRE, that compromise is no longer necessary.

Cell and tissue cultures are grown directly on stretchable MEAs, allowing seamless mechanical and electrical interfacing with the same culture. This integrated approach enables experiments that more closely replicate the conditions cells experience in living organisms.

Unique Value Proposition and Benefits of MEASSuRE

A. Concurrent Mechanical, Optical and Electrical Interface with a Cell Culture: MEASSuRE uniquely combines three modes of interaction—mechanical, optical, and electrical—within a single platform, delivering multiple benefits:

Direct comparison of pre- and post-stretch electrophysiology: Because the microelectrodes stretch elastically with the cells or tissue, they remain in contact with the same locations before, during, and after mechanical stimulation. This enables direct normalization of post-stretch electrophysiological activity to pre-stretch baseline levels—a capability enabled by BMSEED’s patented stretchable electrode technology.

Repeated stretch and relaxation protocols: The elastic nature of sMEAs allows cyclic and repeated stretching, supporting studies of repetitive injury (e.g., concussion models), as well as applications in organ-on-chip systems and regenerative medicine.

Direct verification of tissue strain: Cellular strain does not always match substrate strain due to variations in adhesion and tissue mechanics. MEASSuRE maintains cells within the focal plane during stretching, enabling continuous optical imaging with a built-in high-speed camera. BMSEED’s MATLAB-based image analysis software allows precise quantification of actual cellular strain throughout the experiment.

Improved convenience and efficiency: By combining mechanical stimulation, electrophysiology, and imaging in one system, MEASSuRE saves laboratory space, time, and experimental complexity compared to using multiple standalone instruments.

B. High Reproducibility of Mechanical Strain: MEASSuRE uses a voice coil actuator (VCA) to generate mechanical strain by pulling the stretchable MEA over a cylindrical indenter. Integrated position sensing and a closed-loop PID controller ensure precise, repeatable strain profiles with high experimental reproducibility.

C. High Versatility and Programmability: Researchers can program custom stretch profiles—within defined acceleration, velocity, and stroke limits—using flexible macro-based control. This allows simulation of a wide range of physiological and pathological mechanical conditions.

D. High Strain Capability: MEASSuRE supports strains of up to 50%, enabling studies of both normal tissue mechanics and extreme injury models.

E. High Strain Rates: The low-friction VCA enables high strain rates exceeding 90 s⁻¹, supporting rapid deformation models relevant to traumatic injury research.

F. Radial and Linear Strain in One System: Both radial and linear strain can be generated using the same MEASSuRE platform. Researchers simply exchange the indenter type, eliminating the need for separate devices.

G. Best-Value Integrated System: The MEASSuRE platform is priced below the combined cost of three separate systems for mechanical stimulation, electrophysiology, and imaging—delivering a best-value solution for physiologically relevant in vitro research.

How MEASSuRE Works

Morrison et al., Journal of Neuroscience Methods, 150:192, 2006.

The cells are stretched by pulling the silicone membrane with the embedded microelectrodes over the indenter. The electrodes stretch with the tissue, thus being able to record neural activity before and after stretching from the same location.

Assess Cell Health & Maturity with Electrophyiological Measurements

Before Stretching: The electrodes record neural activity prior to cell stretching.

During Stretching: The stretchable electrodes move with the tissue during the stretching motion.

After Stretching: The stretchable electrodes record neural activity from the same location as before the stretching motion.

Properties of BMSEED’s stretchable multielectrode arrays (sMEAs):

Flexible, Stretchable, and Soft

Recording and Stimulation of Electrophysiological Activity

Mechanically Robust: stretch, bend, twist

How is the mechanical stretch applied to a tissue slice grown on a multielectrode array

How stretchable multielectrode arrays work with MEASSuRE:

The cells are stretched by pulling the silicone membrane of the multielectrode array with the embedded microelectrodes over an indenter. The electrodes stretch with the tissue, thus being able to record neural activity before and after stretching from the same location.

Electron microscopy image of a microcracked gold film.

How is this possible?

Microcracked gold films offer a combination of desirable properties:

low electrical impedance

elastically stretchable

low elastic modulus

low fatigue

inexpensive

BMSEED has an exclusive license for all applications (US Patent 7,491,892)

Why is it important that the gold film is microcracked?

Microcracked gold film on PDMS (sMEAs)

Microcracked gold films can be stretched by over 70% while remaining electrically conductive.

Smooth (no features) gold film on PDMS

Smooth gold films rupture at strains less than 2% and cease to electrically conduct.

Controlling the morphology is therefore very important. To control the morphology of the gold film requires knowledge of the process parameters that affect the morphology:

elastic modulus

pre-treatment of the silicone

film thickness

deposition temperature

adhesion layer

Cells in the Body are Exposed to Two Types of Mechanical Environments

Physiological stretch, where the cells are stretched within their healthy limits: The differentiation of stem cells into a specific cell type is regulated by micro-environmental cues, such as chemical factors, mechanical forces, and electrical fields. Existing products to direct the differentiation of stem cells are using chemical factors alone, or in combination with either mechanical forces or electrical fields. MEASSuRE provides the only method for researchers to manipulate these three factors independently, which will allow for the generation of organs and tissue that resemble the mature organs in vivo more closely than current approaches, i.e., they will more closely replicate the complexity of the human body.

Pathological stretch, where cells are stretched beyond their healthy limits, causing a trauma: MEASSuRE reproduces the biomechanics of a neurotraumatic injury (traumatic brain injury, TBI; spinal cord injury, SCI) or muscle injury in a controlled environment in vitro. The electrodes in the stretchable MEA stretch with the cells/tissue, i.e., they remain in contact with the same location on the tissue before, during, and after stretching. This capability allows for a direct, straightforward assessment of the damage to the injured cells by comparing the electrophysiology (e.g., signal amplitude and frequency) of the cells post-injury to pre-injury level, i.e., MEASSuRE is a screening platform to assess the efficacy of drugs and other treatment strategies for neurotraumatic injuries. The screening is based on the electrophysiology of the injured cells and tissue slices. The electrodes in sMEAs are elastically stretchable, i.e., they also allow the investigation of repeated injuries of the same cells/tissue, e.g., to investigate the cellular and molecular mechanisms of repeated concussions (mild TBI), which is poorly understood.

MEASSuRE serves as a platform to enable fundamentally improved methods to investigate physiological stretch and pathological stretch of cells in a controlled in vitro environment. In addition, MEASSuRE allows optical imaging of the cells throughout the stretching process for verification of the tissue strain and to detect morphological changes in the tissue.